Unlocking Innovation with Top US Based PCB Manufacturers for Your Project Needs

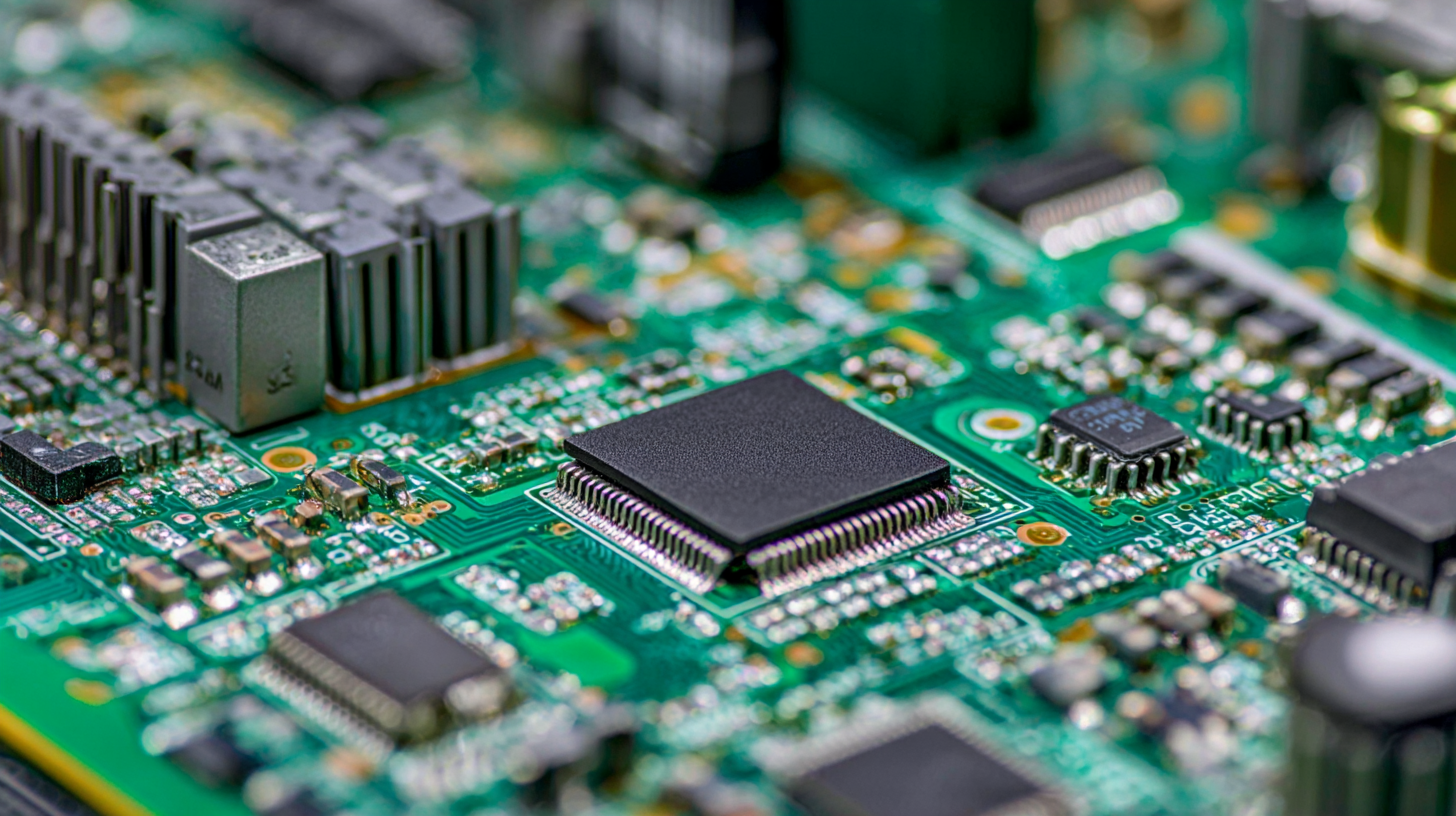

In today's fast-paced technological landscape, the role of innovation in product development has never been more critical. Whether you're embarking on a groundbreaking electronic project or enhancing an existing prototype, collaborating with top US based PCB manufacturers can significantly streamline your process. These manufacturers offer a wealth of expertise, advanced facilities, and a deep understanding of industry standards, allowing you to unlock new levels of creativity and efficiency in your designs. By harnessing the capabilities of US based PCB manufacturers, you can ensure that your printed circuit boards are not only reliable and high-quality but also tailored to meet your specific project requirements. This guide aims to equip you with the essential tips and insights needed to navigate the landscape of PCB manufacturing, enabling you to make informed decisions that propel your innovations forward.

In today's fast-paced technological landscape, the role of innovation in product development has never been more critical. Whether you're embarking on a groundbreaking electronic project or enhancing an existing prototype, collaborating with top US based PCB manufacturers can significantly streamline your process. These manufacturers offer a wealth of expertise, advanced facilities, and a deep understanding of industry standards, allowing you to unlock new levels of creativity and efficiency in your designs. By harnessing the capabilities of US based PCB manufacturers, you can ensure that your printed circuit boards are not only reliable and high-quality but also tailored to meet your specific project requirements. This guide aims to equip you with the essential tips and insights needed to navigate the landscape of PCB manufacturing, enabling you to make informed decisions that propel your innovations forward.

Identifying Your Project Requirements for PCB Manufacturing Success

When embarking on a PCB manufacturing project, identifying your specific requirements is crucial for success. Understanding the functionality, size, and complexity of your PCB will guide you in selecting the right manufacturer. Begin by detailing your project's objectives, such as whether it will be used for a prototype or mass production. This clarity will not only streamline the manufacturing process but also help you communicate effectively with potential manufacturers.

Tips: Engage with your engineering team early in the process to compile a comprehensive list of specifications, including material preferences, layer counts, and any specific certifications required for your industry. This step will ensure that the manufacturer understands your vision and can deliver accordingly.

Additionally, consider the production timeline and budget. High-quality PCB manufacturers within the US offer a variety of services, but aligning your expectations regarding lead times and costs is essential. A well-defined project timeline will help you avoid delays and ensure that the manufacturing aligns with your schedule.

Tips: Research manufacturers that can accommodate your specific volume needs and inquire about their production capabilities. Look for companies that demonstrate flexibility in meeting both your budget constraints and technical specifications, as this can make a significant impact on your project's overall success.

Evaluating Top US PCB Manufacturers: Key Factors to Consider

When evaluating top US PCB manufacturers for your project needs, several critical factors should be taken into account. The U.S. aerospace and defense PCB market is projected to grow from $2.23 billion in 2025 to $2.96 billion by 2032, indicating a robust demand for high-quality materials and innovative designs. As competition intensifies, selecting a manufacturer with a proven track record in advanced technologies and compliance with international standards can significantly impact your project outcomes.

Tip: Look for manufacturers that possess certifications relevant to your industry, as these can ensure that they meet stringent quality and safety requirements. Additionally, consider their capacity for custom solutions and the ability to scale production based on your project’s evolving demands.

Another factor to consider is the geopolitical landscape and its influence on the semiconductor supply chain. Recent tariff discussions highlight the delicate balance manufacturers must strike in sourcing materials globally. Choosing a manufacturer that remains resilient amid these challenges is vital for long-term partnerships.

Tip: Evaluate a manufacturer’s supply chain transparency. A company that communicates openly about their sourcing and production practices is more likely to navigate potential disruptions effectively.

Streamlining Communication with PCB Manufacturers for Effective Collaboration

Effective communication with PCB manufacturers is crucial for successful project execution. A recent report from IPC indicates that 74% of electronics manufacturers believe improved communication with suppliers leads to better product quality and faster time-to-market. This statistic highlights the need for streamlined interactions that can significantly enhance collaboration, ensuring projects meet deadlines and quality standards.

To facilitate better communication, consider utilizing digital platforms that allow real-time updates and feedback. This not only helps in aligning design specifications but also mitigates potential misunderstandings. Additionally, set regular check-in points throughout the manufacturing process. This keeps everyone on the same page and allows for quick adjustments if needed, ultimately fostering a smoother workflow.

**Tips for Effective Collaboration:**

1. Establish clear expectations at the project's outset to avoid scope creep.

2. Utilize dedicated project management tools to track progress and manage documentation.

3. Encourage open dialogue by scheduling regular meetings where all parties can share concerns and insights.

Engaging with top US-based PCB manufacturers while prioritizing effective communication is key to unlocking innovation and ensuring project success.

PCB Manufacturers Performance Comparison

Navigating the Design Process: Best Practices for PCB Prototyping

In today's fast-paced technological landscape, seamless PCB prototyping is crucial for bringing innovative ideas to life. As you embark on your design process, understanding the nuances of rapid PCB manufacturing can give your project a significant edge. Recently, notable developments showcased the efficiency of advanced PCB manufacturers, demonstrating the ability to complete intricate designs within incredibly tight timelines. This trend emphasizes the importance of selecting the right partner for your PCB needs, one that can adapt swiftly to the demands of your project.

In today's fast-paced technological landscape, seamless PCB prototyping is crucial for bringing innovative ideas to life. As you embark on your design process, understanding the nuances of rapid PCB manufacturing can give your project a significant edge. Recently, notable developments showcased the efficiency of advanced PCB manufacturers, demonstrating the ability to complete intricate designs within incredibly tight timelines. This trend emphasizes the importance of selecting the right partner for your PCB needs, one that can adapt swiftly to the demands of your project.

Tips for PCB Prototyping:

First, ensure clear communication of your design specifications to avoid any misunderstandings that could lead to costly revisions. Secondly, take advantage of design software that integrates with manufacturing processes, streamlining your workflow from conception to production. Lastly, consider utilizing manufacturers with proven track records in speed and accuracy, as their expertise will enhance the reliability of your prototypes.

By adhering to these best practices and partnering with the leading PCB manufacturers, you can optimize your design process and unlock greater innovation for your projects.

Ensuring Quality Control: Testing and Certification Standards in PCB Production

In the rapidly evolving world of electronics, quality control is paramount, particularly in the realm of printed circuit board (PCB) production. The meticulous process of testing and certification ensures that PCBs meet the rigorous standards necessary for reliability and performance. Leading US-based PCB manufacturers adhere to industry best practices, implementing stringent quality control measures throughout the production lifecycle. This involves thorough inspections, advanced testing methodologies, and compliance with internationally recognized certification standards such as ISO and IPC.

Manufacturers perform a variety of tests, including electrical testing, thermal profiling, and environmental stress tests, to validate the functionality and durability of their products. Certification processes not only enhance the credibility of the manufacturer but also provide assurance to clients that the PCBs are capable of enduring real-world applications. Thus, when partnering with top-tier PCB manufacturers, clients can rest assured that their projects are backed by rigorous quality assurance protocols, fostering innovation while minimizing the risks associated with electronic component failures.

Related Posts

-

Understanding the Impact of Printed Circuit Board Assembly on Today's Electronics Industry and Market Growth

-

Master the Art of Circuit Design Software for Innovative Electronics Solutions

-

Unlocking Efficiency: The Future of PCB Production Techniques in Modern Electronics

-

Understanding the Importance of Circuit Board Assembly in Modern Electronics

-

The Future of Electronics Innovating with PCB Design Software for Beginners

-

Innovative Trends in PCB Printing That Will Transform the Electronics Industry