Top 5 US Based PCB Manufacturers to Watch in 2025

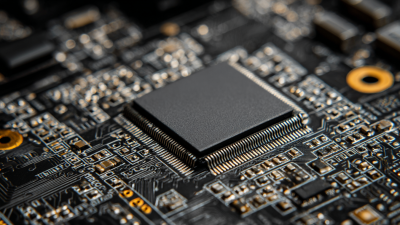

As the electronics industry continues to evolve, the demand for high-quality printed circuit boards (PCBs) is surging. With the rise of advanced technologies and a growing focus on domestic manufacturing, the spotlight is on US based PCB manufacturers. According to Dr. Emily Chen, a leading expert in electronics manufacturing, “The innovation and reliability of US based PCB manufacturers are crucial for the future of technology development in our country.”

In 2025, these manufacturers are poised to not only meet the needs of a competitive market but also set new standards in quality and efficiency. With increasing capabilities in automation and sustainable practices, they are adapting to the dynamic demands of industries ranging from automotive to consumer electronics. The continual advancement in PCB technology will likely allow US based PCB manufacturers to enhance their offerings, contributing significantly to the global supply chain.

In this article, we will delve into the top five US based PCB manufacturers to keep an eye on as they lead the charge in innovation and service excellence. By exploring their unique strengths and contributions, we aim to provide valuable insights into what makes these companies standout players in the unfolding landscape of printed circuit board manufacturing.

Emerging Trends in PCB Manufacturing Technologies for 2025

As we approach 2025, significant trends in PCB manufacturing technology are surfacing that could redefine the industry landscape. One noteworthy trend is the ongoing miniaturization of electronic components, allowing for seamless and versatile designs. This shift not only enhances the aesthetic appeal of gadgets but also improves functionality and performance in compact devices. The Emerging Technologies in Manufacturing Market Research Report indicates that the market is projected to grow from approximately $226.6 million in 2024 to about $1.15 billion by 2025, reflecting the increasing demand for advanced PCB technologies.

Another critical development is the integration of bio-microsystem technologies, particularly Lab-on-PCB systems. These advancements enable the creation of micro-total analysis systems (µTAS), significantly impacting sectors like healthcare and environmental monitoring. As companies invest in these innovative solutions, staying updated on emerging technologies and trends becomes vital.

**Tip:** To maintain a competitive edge, consider collaborating with startups focusing on cutting-edge PCB technologies. Their fresh perspectives can lead to breakthrough innovations that enhance your product offerings. Additionally, investing in advanced manufacturing technologies could streamline your production processes significantly.

Market Growth Projections for US PCB Manufacturers and Global Competitiveness

The market for Printed Circuit Boards (PCBs) in the United States is poised for significant growth in the coming years, with projections indicating a robust demand driven by advancements in technology and increasing applications across various industries. The PCB Design Software market, for instance, is expected to grow at a staggering CAGR of 13.77%, reaching an approximate value of USD 12.11 billion by 2033. This surge reflects the broader trend towards enhanced digitalization and electronic integration in products, underscoring the critical role PCBs play in the modern technological landscape.

As global competitiveness intensifies, US PCB manufacturers are strategically positioning themselves to capitalize on emerging opportunities. Notably, changes in supply chains, influenced by reciprocal tariffs and talent bottlenecks, are prompting shifts in investment strategies, particularly towards Southeast Asia. However, US manufacturers are expected to innovate and expand their capabilities to maintain their market presence. The anticipated growth in demand for PCB assembly, projected to reach USD 161.6 billion by 2035, highlights the necessity for manufacturers to adapt swiftly to market dynamics while enhancing their competitive edges through technological advancements and strategic partnerships.

Top Innovations in PCB Design and Production Techniques Expected in 2025

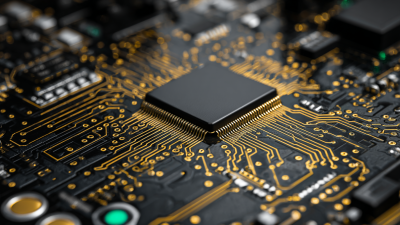

As we look toward 2025, the printed circuit board (PCB) industry is poised for significant innovations in design and production techniques. One of the most promising advancements is the integration of advanced materials such as flexible substrates and high-frequency laminates. These materials not only enhance the functionality of PCBs but also enable the development of thinner, lighter, and more resilient products. This shift will cater to the growing demands in sectors like telecommunications and automotive, where high-performance and compact designs are crucial.

Moreover, the rise of automation and artificial intelligence in PCB manufacturing is set to revolutionize the production process. Smart manufacturing techniques, including robotics for assembly and AI-driven quality control systems, will lead to increased efficiency and reduced error rates. Additionally, innovations in 3D printing technology are expected to facilitate rapid prototyping and customization, allowing manufacturers to respond quickly to market needs. As these trends unfold, the landscape of PCB manufacturing in the US will transform, highlighting the importance of staying ahead in this dynamic industry.

Top 5 US Based PCB Manufacturers to Watch in 2025 - Top Innovations in PCB Design and Production Techniques Expected in 2025

| Rank | Innovation Type | Description | Expected Impact | Market Segment |

|---|---|---|---|---|

| 1 | Flexible PCBs | Development of thinner and more flexible circuit boards for wearable technology. | Enhanced portability and comfort in wearable devices. | Consumer Electronics |

| 2 | High-density interconnect (HDI) | Advancements in multi-layer PCB designs for compact devices. | More efficient designs leading to smaller yet powerful devices. | Telecommunications |

| 3 | Automated Manufacturing | Implementation of AI and robotics in PCB production lines. | Increased production efficiency and reduced human error. | Industrial Automation |

| 4 | Green Materials | Use of biodegradable and recyclable materials in PCB manufacturing. | Reduced environmental impact and enhanced sustainability. | Consumer Electronics, Automotive |

| 5 | 3D Printing | Adoption of 3D printing techniques for PCB prototyping and production. | Faster prototyping resulting in shorter time-to-market. | Rapid Prototyping and Manufacturing |

Key Factors Influencing PCB Quality and Reliability in the Next Decade

In the rapidly evolving landscape of electronics, the quality and reliability of printed circuit boards (PCBs) are paramount. As we look towards 2025, several key factors are set to influence PCB performance. First and foremost, the materials used in the manufacturing process are critical. Advanced materials like high-frequency laminates and improved epoxy resins can significantly enhance thermal stability and signal integrity. As manufacturers strive to meet higher standards, they must invest in research and development to discover new materials that offer superior performance.

Tips: When selecting a PCB manufacturer, consider their investment in materials. Manufacturers that prioritize high-quality raw materials are more likely to deliver reliable products. Additionally, scrutinize their certifications and adherence to industry standards, which can be indicative of their commitment to quality.

Another critical aspect is the adoption of advanced manufacturing technologies. Innovations such as automated assembly processes and precision laser cutting have shown to reduce human error and increase production efficiency. These advancements not only improve the overall quality of PCBs but also allow for faster turnaround times.

Tips: Always inquire about a manufacturer’s technological capabilities. A company that embraces cutting-edge production techniques is likely to provide better quality assurance and faster delivery times, ultimately benefiting your project timeline.

Leading US PCB Manufacturers and Their Strategic Initiatives for 2025

As we approach 2025, the landscape of PCB manufacturing in the U.S. is rapidly evolving, marked by innovation and strategic initiatives aimed at meeting the demands of a tech-driven world. Leading manufacturers are not only investing in advanced fabrication technologies but are also focusing on sustainability and efficient supply chain management. Companies like Advanced Circuits and Sierra Circuits are enhancing their capabilities through automation and AI to streamline production processes, reduce lead times, and improve overall quality.

In addition to technological advancements, these manufacturers are forming strategic partnerships and collaborations to expand their market reach and diversify their product offerings. By aligning with tech firms and research institutions, they aim to leverage cutting-edge developments in materials science and electronics design. Such initiatives not only bolster their competitive stance but also pave the way for innovative solutions in emerging sectors like electric vehicles and IoT devices, positioning them as key players in the future of the PCB industry.

Related Posts

-

Innovative Trends in PCB Printing That Will Transform the Electronics Industry

-

Discover the Top PCB Manufacturers Near Me: Your Ultimate Guide to Local Electronics Solutions

-

Transforming Industries: The Future of PCB Production and Its Impact on Technology

-

Unlocking Efficiency: The Future of PCB Production Techniques in Modern Electronics

-

10 Essential Tips for Finding the Best PCB Manufacturers Near Me

-

Top 5 Essential Features of High Quality PCB Boards for Your Projects