Top 10 Tips for Efficient Circuit Board Manufacturing Process Optimization

In today's fast-paced electronics industry, the demand for high-quality circuit boards is continuously rising, driven by advancements in technology and growing consumer expectations. According to a report by Research and Markets, the global printed circuit board (PCB) market is projected to reach approximately USD 83 billion by 2026, expanding at a compound annual growth rate (CAGR) of 4.8% from 2021 to 2026. This highlights the critical need for efficient circuit board manufacturing processes that not only enhance productivity but also reduce costs.

Optimizing the circuit board manufacturing process is vital for companies aiming to remain competitive in this dynamic market. With the increase in miniaturization and complexity of electronic devices, manufacturers face new challenges, such as maintaining stringent quality standards while optimizing lead times. In this context, implementing best practices and leveraging advanced technologies can lead to significant improvements. Industry experts assert that well-optimized manufacturing processes can reduce production costs by up to 30%, making it essential for businesses to focus on process optimization strategies.

By adopting innovative techniques and staying informed about industry best practices, manufacturers can streamline their operations, improve yield rates, and ultimately deliver superior products to their customers. This article presents the top 10 tips for enhancing the circuit board manufacturing process, ensuring manufacturers can capitalize on the growth opportunities within this lucrative market.

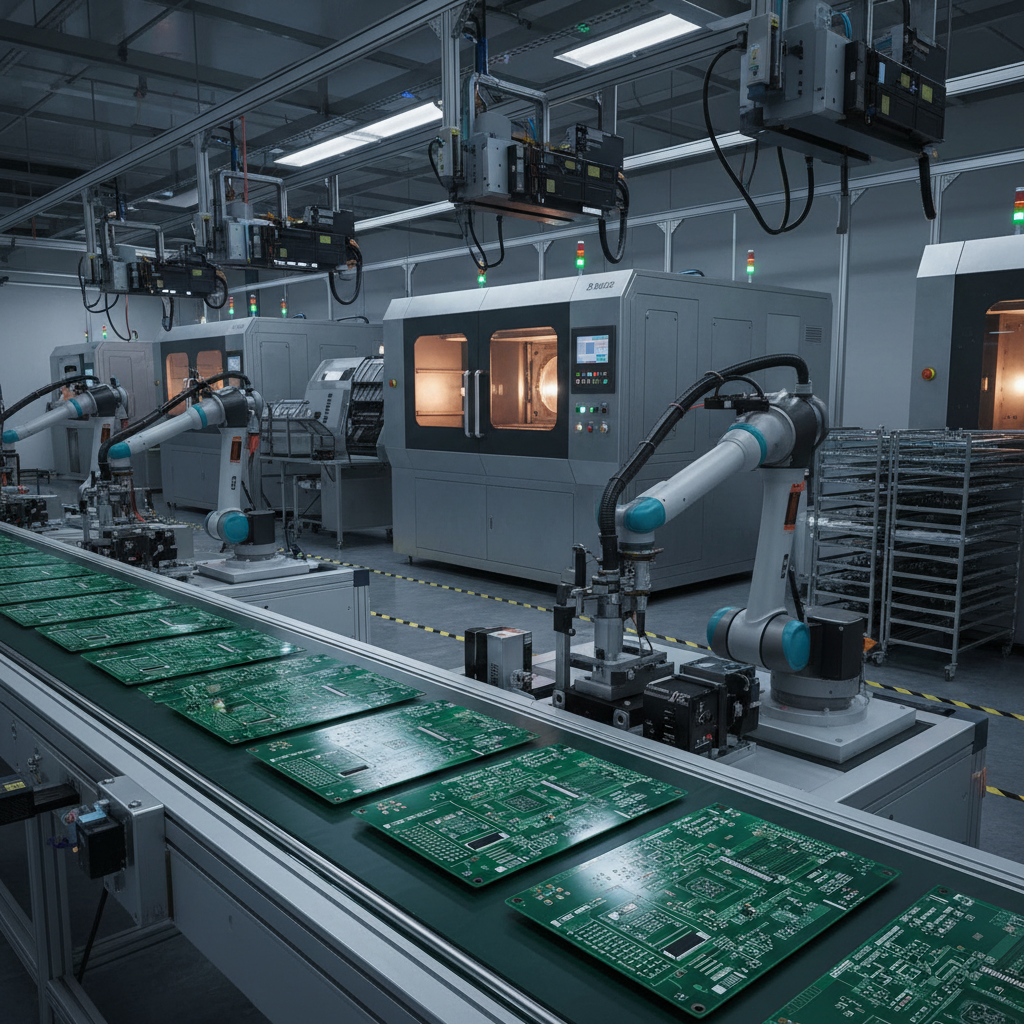

Strategies for Integrating Automation Technologies in PCB Manufacturing Processes

The integration of automation technologies in PCB manufacturing processes is becoming increasingly crucial as the industry evolves. With enhanced capabilities, off-line PCB laser depaneling systems are poised for significant growth. Projected to be valued at $141.41 million in 2024 and reaching $203.26 million by 2032, this market represents a compound annual growth rate of 4.7%. Adopting such automated solutions not only boosts efficiency but also improves precision during the manufacturing process.

To optimize the manufacturing workflow, consider these tips. First, implement real-time monitoring systems that provide up-to-date data on production performance. This allows for immediate adjustments, reducing downtime and waste. Second, invest in advanced EDA tools that streamline design processes and improve collaboration. By leveraging automation in design and production, manufacturers can enhance productivity and reduce errors, paving the way for a more agile manufacturing environment.

Additionally, fostering a culture of continuous improvement is essential. Regularly assess and upgrade automation technologies to keep pace with industry advancements. By staying ahead of the curve, PCB manufacturers can ensure they remain competitive in a rapidly changing market landscape.

The Impact of Real-Time Data Analytics on Production Efficiency in Circuit Board Manufacturing

The implementation of real-time data analytics in circuit board manufacturing stands as a pivotal shift towards enhancing production efficiency. By leveraging machine learning and deep learning techniques, manufacturers can analyze data at every stage of the manufacturing process, from design to assembly. This allows for immediate feedback and adjustments, reducing errors and streamlining operations. The ability to access and interpret real-time data helps businesses maintain a competitive edge, ensuring that they can meet market demands without overproducing.

To optimize the circuit board manufacturing process, manufacturers can employ several key tips. First, implementing predictive analytics can help identify potential bottlenecks before they occur, enabling smoother workflows. Second, integrating IoT devices facilitates improved monitoring of production lines, providing insights that lead to better resource allocation. Lastly, fostering an environment of human-machine collaboration enhances decision-making capabilities, blending human expertise with the speed and accuracy of AI.

As the industry progresses towards 2026, these strategies, backed by significant technology investments, will be essential for maintaining operational efficiency and responding agilely to market changes. This focus on real-time analytics is not merely a trend but a necessary evolution in the manufacturing landscape.

Optimizing Supply Chain Management to Reduce PCB Production Lead Times and Costs

In the highly competitive landscape of printed circuit board (PCB) manufacturing, optimizing supply chain management is crucial for reducing production lead times and costs. According to a recent study by IPC, manufacturers can cut lead times by up to 20% by adopting just-in-time (JIT) inventory practices, eliminating waste, and ensuring timely delivery of components. Enhancing supplier relationships also plays a vital role; by collaborating closely with suppliers, firms can forecast demand more accurately, leading to improved inventory turnover and reduced holding costs.

One effective tip is to implement an integrated supply chain management system that uses real-time data analytics. This technology can provide visibility into the supply chain, allowing manufacturers to react swiftly to changes in demand or supply disruptions. Another key suggestion is to standardize component specifications across different projects. According to a report from the Institute of Printed Circuits, standardization can reduce procurement times by nearly 30% while enhancing quality control measures.

Investing in automated procurement processes can also yield significant benefits. Automating repetitive tasks not only saves time but also minimizes errors associated with manual handling. By leveraging automation, PCB manufacturers can foster a more agile and responsive supply chain that ultimately drives down production costs and improves overall efficiency.

Implementing Lean Manufacturing Principles to Minimize Waste in Circuit Board Production

Implementing lean manufacturing principles in circuit board production is crucial for minimizing waste and enhancing efficiency. One of the key strategies involves identifying and eliminating non-value-added activities throughout the manufacturing process. This can include streamlining workflows, optimizing equipment usage, and simplifying material handling. By conducting value stream mapping, manufacturers can visualize the entire production cycle and pinpoint areas where waste, such as excess movement or waiting times, occurs. This transformation not only cuts down on unnecessary costs but also accelerates overall production timelines.

Another essential aspect of lean manufacturing is fostering a culture of continuous improvement among employees. Encouraging team members to contribute ideas for process enhancements can lead to significant improvements in production efficiency. Techniques like Kaizen workshops, where small, incremental changes are implemented, can pave the way for innovation and adaptability in circuit board manufacturing. By adopting a mindset that values efficiency and minimizes waste, companies can ensure a more sustainable production model that meets the demands of the ever-evolving electronics market.

Enhancing Quality Control Systems to Improve Yield Rates in PCB Manufacturing Operations

In the rapidly evolving landscape of PCB manufacturing, enhancing quality control systems is paramount to improving yield rates. Efficient circuit board manufacturing processes must prioritize the integration of advanced inspection technologies, particularly as the global semiconductor defect inspection equipment market anticipates significant growth. By incorporating automated inspection solutions, companies can quickly identify defects and implement corrective actions, thereby reducing waste and increasing overall efficiency.

One effective tip for optimizing the PCB manufacturing process is to adopt real-time monitoring and analytics. This approach allows manufacturers to track production metrics continuously and make data-driven decisions to enhance quality control. Additionally, embracing artificial intelligence in inspection processes can revolutionize traditional methods by providing predictive insights that minimize errors.

Another crucial aspect involves fostering a culture of continuous improvement among the workforce. Training employees on quality standards and encouraging proactive problem-solving can lead to innovative solutions that enhance productivity. By focusing on these strategies, PCB manufacturers can navigate the complex challenges of the industry while boosting yield rates and ensuring top-notch quality in their products.

Related Posts

-

Top 5 US Based PCB Manufacturers to Watch in 2025

-

Discover the Top PCB Manufacturers Near Me: Your Ultimate Guide to Local Electronics Solutions

-

Transforming Industries: The Future of PCB Production and Its Impact on Technology

-

Unlocking Efficiency: The Future of PCB Production Techniques in Modern Electronics

-

Understanding the Impact of Printed Circuit Board Assembly on Today's Electronics Industry and Market Growth

-

Innovative Trends in PCB Printing That Will Transform the Electronics Industry