2025 Top 5 Trends in Circuit Board Design You Can't Afford to Miss

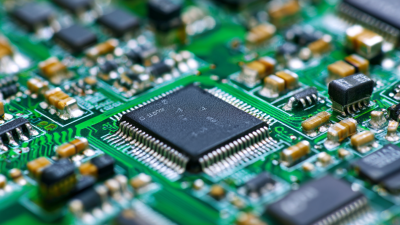

As we look toward the future of circuit board design, staying ahead of the curve is critical for engineers and designers committed to innovation. The global market for circuit boards is projected to reach $100 billion by 2025, fueled by advancements in consumer electronics, automotive technologies, and the Internet of Things (IoT). According to a recent report by IBISWorld, the demand for sophisticated circuit board designs will increase by 4% annually, emphasizing the necessity for professionals to embrace emerging trends that could redefine the landscape.

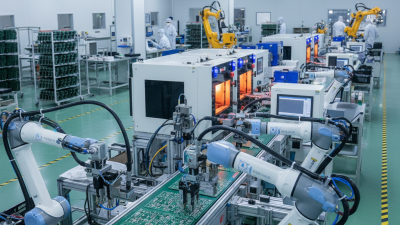

In this rapidly evolving industry, we are witnessing a significant shift towards more sustainable and efficient manufacturing processes. A study from Research and Markets highlights the growing emphasis on eco-friendly materials, which are set to dominate the circuit board design market, reflecting the industry's commitment to reducing environmental impact. Additionally, with the advent of artificial intelligence and machine learning, circuit board design is poised for unprecedented optimization, promising faster development cycles and enhanced performance.

Understanding these trends is not just beneficial; it is essential for any stakeholder looking to maintain a competitive edge in circuit board design. In the following sections, we will explore the top five trends shaping the future of this vital industry, ensuring that you are well-equipped to navigate the challenges and opportunities that lie ahead.

Impact of AI and Machine Learning on Circuit Board Design Efficiency

The integration of AI and machine learning into circuit board design is revolutionizing the industry, drastically improving efficiency and accuracy. According to a report by ResearchAndMarkets, the global market for AI in electronic design automation is expected to grow at a CAGR of 45.3% from 2021 to 2026. This surge is primarily driven by the increasing complexity of electronic systems and the need for faster production cycles. AI algorithms can analyze vast datasets to optimize layout designs, leading to significant reductions in development time and costs.

Tips: To leverage AI effectively in circuit board design, design teams should invest in training sessions to help engineers understand machine learning models and their applications. Emphasizing collaboration between cross-functional teams will also ensure that insights from machine learning are effectively integrated into the design process.

Moreover, AI-powered design tools are capable of predicting potential failures and identifying design flaws early in the development stage, enhancing the overall quality of the final product. As highlighted in a report by Deloitte, companies that harness machine learning in their design workflow experience up to a 30% increase in productivity. Embracing these technologies not only streamlines operations but also positions firms at the forefront of innovation within the competitive landscape.

Tips: It's beneficial for teams to adopt prototype simulations that utilize AI for testing and validation, allowing for real-time adjustments and improvements before physical fabrication.

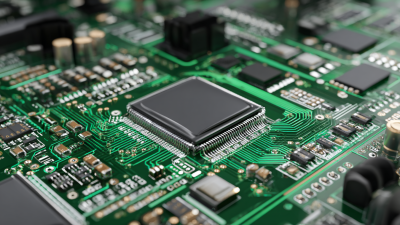

Advancements in Flexible Circuit Technologies for Enhanced Applications

The advancements in flexible circuit technologies are reshaping the landscape of electronic design, offering unparalleled versatility and performance. Flexible circuits, distinguished by their ability to bend and conform to various shapes, are becoming integral to a myriad of applications—from consumer electronics to medical devices. This flexibility not only allows for innovative designs but also significantly reduces space and weight, making them ideal for modern, compact devices. The evolution of materials and manufacturing processes has enhanced the durability and reliability of these circuits, ensuring they meet the rigorous demands of today's high-performance applications.

Moreover, the integration of smart features into flexible circuits opens up new possibilities in IoT and wearable technology. These next-generation circuits can seamlessly incorporate sensors and actuators, paving the way for smart textiles and responsive environments. As the industry continues to innovate, engineers are now able to design circuits that not only support advanced functionalities but also adapt to the user's needs in real-time. Such advancements position flexible circuit technologies at the forefront of electronic design, enabling a future where connectivity and functionality interplay more closely than ever before.

Sustainability in Circuit Board Manufacturing: Eco-friendly Innovations

Sustainability is rapidly becoming a cornerstone in the realm of circuit board manufacturing. Manufacturers are increasingly adopting eco-friendly innovations to minimize their environmental impact. This involves the use of sustainable materials, such as bioplastics and recyclable metals, which reduce waste and promote a circular economy. Additionally, companies are exploring energy-efficient processes, utilizing renewable energy sources, and implementing waste reduction strategies to ensure that their operations align with global sustainability goals.

Tips for embedding sustainability into your circuit board design include selecting suppliers who prioritize environmental responsibility and adopting designs that require fewer materials. Consider using lead-free solder and other non-toxic components to enhance the eco-friendliness of your products. Furthermore, engaging in life cycle assessments can help identify areas for improvement, ensuring that your circuit boards are not only effective but also sustainable throughout their lifespan.

Another valuable tip is to embrace advanced manufacturing technologies like additive manufacturing (3D printing), which minimizes material waste and allows for more complex designs without adding extra burden on the environment. Collaborating with industry partners to share best practices in sustainable design can also drive collective progress towards greener manufacturing standards.

Integration of 5G Technology and Its Influence on Design Requirements

The integration of 5G technology is revolutionizing circuit board design by introducing stringent requirements for speed, connectivity, and compactness. As outlined in recent reports, the 5G landscape promises remarkable advancements, boasting speeds that can reach up to 20 Gbps and the capability to connect up to 1 million devices per square kilometer. This extraordinary increase in capacity forces designers to rethink their strategies, focusing on compact and efficient designs that can accommodate enhanced functionalities.

Moreover, emerging trends such as Antenna in Package (AiP) technologies are set to shape the future of circuit boards, particularly to meet the needs of 5G and the anticipated 6G networks. By 2034, these technologies will be crucial in optimizing space and performance, facilitating faster data transmission and reducing latency. Understanding these trends is essential for circuit board designers to stay at the forefront of innovation, ensuring that their designs not only meet current demands but are also adaptable to future challenges in connectivity and technology standards.

Emerging Trends in PCB Materials for Greater Durability and Performance

As the PCB industry witnesses significant advancements, the emerging trends in PCB materials are becoming pivotal for enhancing durability and performance. A key focus is on the growth of electronic-grade bisphenol A epoxy resins, which is projected to see a market value increase from $1.16342 billion in 2023 to approximately $1.20531 billion by 2024. The compound annual growth rate (CAGR) during this period indicates the rising demand and innovation in materials, ultimately reaching an estimated $1.63876 billion by 2032. This trend highlights the industry's move towards more robust and high-performance materials that can withstand the increasing complexities of electronic designs.

Tips: As you explore these material trends, consider investing in training for your team on the latest PCB material technologies to stay competitive. Additionally, incorporating sustainability practices in your design process can enhance your brand’s appeal in a market increasingly focused on eco-friendly solutions.

The advancements don’t stop with just the materials; the choice of manufacturing processes and techniques is equally critical in achieving superior performance. Embracing new technologies like additive manufacturing and enhanced thermal management strategies can significantly improve the reliability and functionality of PCBs in various applications, from consumer electronics to aerospace. Staying ahead in these trends will not only optimize product performance but also ensure long-term client satisfaction.

2025 Top 5 Trends in Circuit Board Design You Can't Afford to Miss

| Trend | Description | Material Innovations | Performance Benefits |

|---|---|---|---|

| Flexible PCBs | Increasing use in compact and portable devices. | Polyimide and flexible epoxy resins. | Enhanced durability and weight reduction. |

| High-Frequency Materials | Designed for improved signal integrity in RF applications. | Low-loss F4B, F4B-L, and other advanced ceramics. | Increased data rates and reduced signal loss. |

| Eco-Friendly Materials | Shift towards sustainable and recyclable materials. | Biodegradable FR4 alternatives and recycled materials. | Reduced environmental impact and compliance with regulations. |

| High Thermal Conductivity | Materials that dissipate heat faster for better reliability. | Copper and aluminum based composites. | Improved longevity and performance under thermal stress. |

| Embedded Components | Integration of components directly into the PCB layer. | Advanced materials capable of housing ICs. | Space-saving and enhanced performance. |

Related Posts

-

The Future of Printed Circuit Boards: Innovations Shaping Our Electronic Devices

-

Transforming Industries: The Future of PCB Production and Its Impact on Technology

-

Unlocking Efficiency: The Future of PCB Production Techniques in Modern Electronics

-

Innovative Trends in PCB Printing That Will Transform the Electronics Industry

-

Top 5 Essential Features of High Quality PCB Boards for Your Projects

-

Top 10 Tips for Efficient Circuit Board Manufacturing Process Optimization