How to Get Quick Turn PCB Prototyping for Your Project Needs

In today's fast-paced technological landscape, where innovation drives competitive advantage, the demand for quick turn PCB (printed circuit board) prototyping has skyrocketed. According to a report by the IPC (Association Connecting Electronics Industries), the global PCB market surpassed $60 billion in 2021, with a substantial shift towards short lead times and rapid product development cycles. Businesses across various sectors, from consumer electronics to automotive, are increasingly relying on quick turn PCB services to expedite their product launch timelines and meet the accelerating pace of market demands.

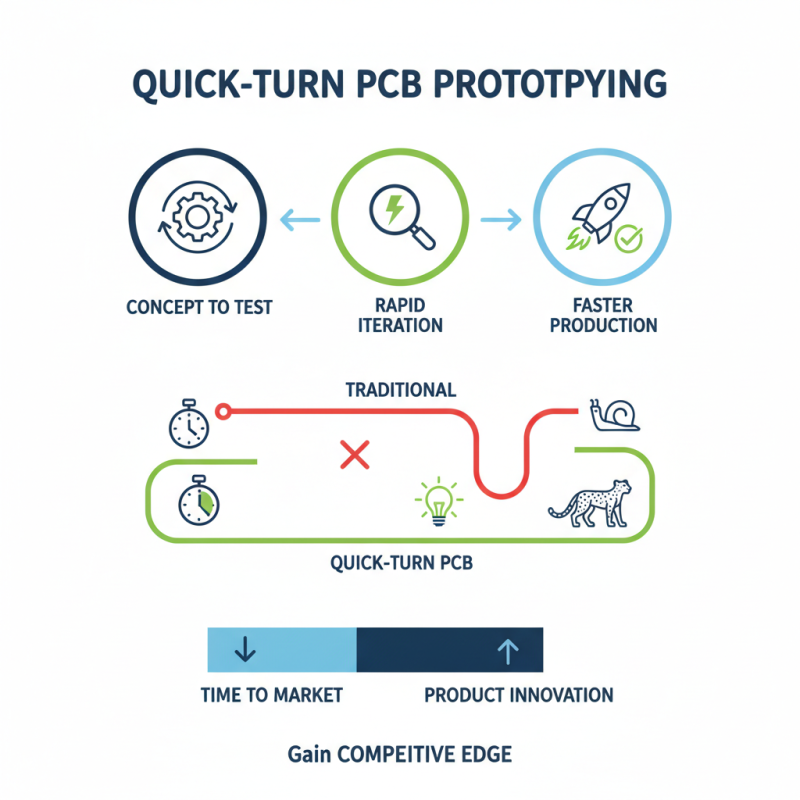

Quick turn PCB prototyping offers significant benefits, enabling engineers and designers to swiftly iterate on designs and incorporate feedback. Research indicates that companies that adopt rapid prototyping strategies can reduce their time-to-market by up to 50%, effectively positioning themselves ahead of competitors. This not only enhances product quality through timely revisions but also fosters innovation by allowing teams to explore and realize complex designs more efficiently. As the industry continues to evolve, prioritizing quick turn PCB capabilities becomes essential for organizations aiming to thrive in the modern technological arena.

Understanding the Importance of Quick Turn PCB Prototyping in Electronics

In the fast-paced world of electronics, the significance of quick turn PCB prototyping cannot be overstated. Rapid prototyping enables engineers and designers to test their ideas and innovations in real-time, reducing the time from concept to production. By streamlining the prototyping process, teams can iterate on designs swiftly, make necessary adjustments, and improve overall product quality before committing to mass production. This agility is crucial in a competitive market where the ability to respond quickly to consumer demands can determine a product's success.

Moreover, understanding the importance of quick turn PCB prototyping helps businesses optimize their resources effectively. With shorter lead times, organizations can allocate their budgets more efficiently, reducing the risk of over-investing in designs that may not meet market needs. This approach encourages experimentation, allowing teams to explore multiple iterations without the fear of significant financial loss. Ultimately, quick turn PCB prototyping fosters innovation, driving the development of cutting-edge technology while ensuring that products are market-ready in a timely manner.

Key Factors Influencing PCB Prototyping Turnaround Time

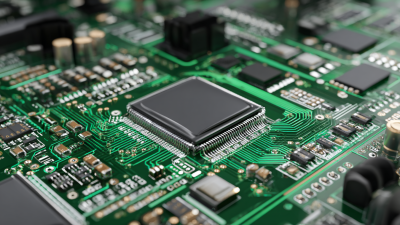

Getting quick turnaround times for PCB prototyping is essential in today’s fast-paced tech environment. Several key factors influence how quickly a PCB prototype can be developed and delivered. Among these factors are design complexity, material choice, manufacturing technology, and the service provider's capabilities. Research indicates that around 65% of PCB delays are attributable to design-related issues, emphasizing the importance of thorough planning and communication during the design phase.

Material selection also plays a crucial role in turnaround time. Certain materials can expedite the manufacturing process, while others may require more intricate handling and additional processes, leading to delays. For instance, utilizing standard FR-4 material generally supports faster prototyping compared to specialized substrates. Similarly, adopting advanced manufacturing technologies like automated assembly and rapid tooling can significantly reduce production times, often by as much as 30% in optimal conditions.

Tips: To enhance your prototyping speed, consider investing in PCB design software that automates error checks and optimization suggestions, reducing design-related delays. Additionally, maintain regular communication with your prototyping provider to ensure alignment and swift resolution of any issues. Lastly, choosing a provider that offers simultaneous engineering support can also save time by allowing troubleshooting during the manufacturing process, rather than after design completion.

Selecting the Right PCB Manufacturer for Rapid Prototyping

When selecting the right PCB manufacturer for rapid prototyping, it's crucial to consider their capabilities and experience in handling quick-turn projects. A reliable manufacturer should demonstrate a robust production process that ensures not only speed but also precision. Look for companies that employ advanced technologies and have a proven track record of meeting tight deadlines without compromising quality. This might involve investigating their machinery, software used for design, and their ability to adapt to last-minute changes.

In addition to technical capabilities, communication and customer support play a significant role in the prototyping process. An ideal PCB manufacturer should maintain clear lines of communication and provide updates throughout the production cycle. This level of engagement helps ensure that your specific requirements are met, and any potential issues are addressed promptly. A strong partnership with your manufacturer can lead to successful prototyping outcomes, allowing for quicker iterations and enhancing the overall development process of your project.

PCB Prototyping Time Efficiency: Manufacturer Comparison

Comparative Cost Analysis of Quick Turn vs. Standard PCB Prototyping

When considering PCB prototyping for your project, the choice between quick turn and standard prototyping can significantly impact your budget and timelines. Quick turn PCB prototyping offers the advantage of expedited production, often completed within days rather than weeks. This service is ideal for engineers and designers who are racing against tight deadlines or who need to validate their designs rapidly before moving into full-scale production. However, this speed comes with a higher cost, as the resources dedicated to achieving shorter lead times and the potential for expedited material sourcing increase overall expenses.

On the other hand, standard PCB prototyping is generally more cost-effective, allowing for a lower upfront investment. This method suits projects with more flexible timelines, where the focus is on thorough testing and iterative design improvements. While standard methods might extend lead times significantly, the savings from reduced pricing can be substantial, particularly for larger projects or organizations with tight budgets. A comparative cost analysis reveals that balancing time constraints with budget allowances is crucial; in some cases, opting for quick turn may be essential, whereas in others, sticking to standard prototyping could provide a more economical route without compromising on quality.

How to Get Quick Turn PCB Prototyping for Your Project Needs - Comparative Cost Analysis of Quick Turn vs. Standard PCB Prototyping

| Prototyping Type | Turnaround Time | Average Cost (USD) | Complexity Level | Common Applications |

|---|---|---|---|---|

| Quick Turn PCB | 1-5 Days | $200 - $1000 | High | Rapid Prototyping, Iterative Designs |

| Standard PCB | 10-20 Days | $100 - $500 | Medium | Consumer Electronics, Large Scale Production |

| Ultra Quick Turn PCB | 24 Hours | $800 - $1500 | Very High | Time-Sensitive Projects, Emergency Repairs |

| Prototype Batch | 5-10 Days | $500 - $1200 | Medium to High | Small Batch Runs, Testing |

Common Challenges and Solutions in Fast PCB Prototyping Process

In the realm of electronics, rapid PCB prototyping has become a crucial aspect of product development. However, various challenges often hinder the speed and efficiency of the process. One of the primary issues is managing design complexity. According to industry reports, nearly 70% of PCB designers encounter difficulties aligning the design specifications with manufacturability—a phenomenon often referred to as "design for manufacturability" (DFM) issues. To overcome this, utilizing advanced software tools that offer DFM analysis can help identify potential flaws in the design stage, thereby shortening the iteration cycle and enabling faster prototyping.

Another common challenge is the sourcing of high-quality materials in a timely manner. A survey from a leading industry publication highlights that 60% of companies face delays due to insufficient inventory of essential components. To mitigate supply chain disruptions, many firms are now adopting just-in-time (JIT) inventory practices, which allow for more responsive and flexible procurement strategies. By establishing strong relationships with multiple suppliers and also considering alternative materials, businesses can improve their turnaround times for PCB prototyping and meet project deadlines more effectively. Employing these strategies not only addresses the immediate problems but also fosters a more robust prototyping framework, setting the stage for more innovative product development.

Related Posts

-

Transforming Industries: The Future of PCB Production and Its Impact on Technology

-

Innovative Trends in PCB Printing That Will Transform the Electronics Industry

-

Top 5 Essential Features of High Quality PCB Boards for Your Projects

-

Top 5 US Based PCB Manufacturers to Watch in 2025

-

Top 10 Printed Circuit Board Manufacturers You Should Know About

-

10 Essential Tips for Finding the Best PCB Manufacturers Near Me