The Future of Printed Circuit Boards: Innovations Shaping Our Electronic Devices

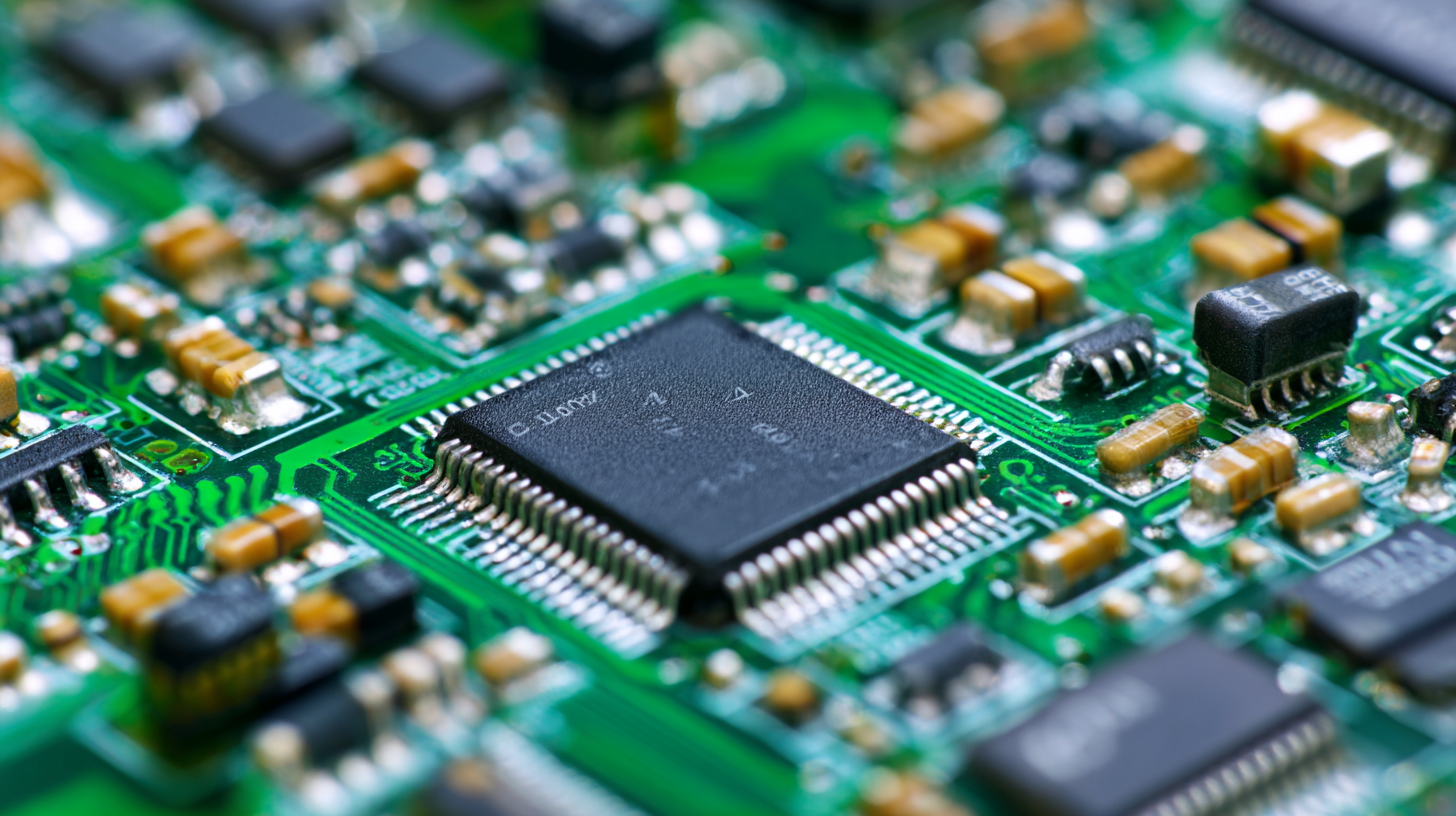

As technology continues to advance at a rapid pace, the role of printed circuit boards (PCBs) in shaping the future of electronic devices becomes increasingly significant. From the compact smartphones we rely on daily to the sophisticated medical equipment revolutionizing healthcare, PCBs serve as the backbone, enabling complex functionalities in a variety of applications. This article explores the latest innovations in printed circuit board design and manufacturing, highlighting how these developments are crucial for enhancing performance, reducing size, and improving sustainability. As we look towards the future, understanding the evolution of PCBs provides valuable insights into the next generation of electronic devices, revealing how these essential components are adapting to meet the ever-changing demands of technology and consumers alike. Join us as we delve into the cutting-edge advancements that are setting the stage for a transformative era in electronics.

Emerging Materials: Revolutionizing PCB Construction and Performance

The landscape of printed circuit board (PCB) technology is undergoing a profound transformation, driven largely by the emergence of innovative materials that enhance both construction and performance. According to a recent industry report by Research and Markets, the global flexible PCB market is projected to grow at a CAGR of 10.1% from 2021 to 2026, highlighting the increasing demand for lightweight and adaptable electronics. Emerging materials such as polytetrafluoroethylene (PTFE) and polyimide are revolutionizing PCB design, allowing for higher thermal stability and improved electrical performance, which are critical for today's sophisticated electronic devices.

Moreover, the integration of advanced composites and nanomaterials is also on the rise. A report by IDTechEx predicts that the market for nanomaterial-based PCBs will surpass $25 billion by 2028, driven by their exceptional properties, including enhanced conductivity and durability. These innovations not only support the miniaturization of electronic components but also improve energy efficiency, paving the way for greener technology. As manufacturers continue to explore these emerging materials, the performance and functionality of printed circuit boards are set to reach unprecedented levels, enabling next-generation electronic devices across various sectors.

The Future of Printed Circuit Boards: Innovations Shaping Our Electronic Devices

| Material Type | Thermal Conductivity (W/m·K) | Dielectric Constant | Mechanical Strength (MPa) | Cost (USD/kg) |

|---|---|---|---|---|

| FR-4 | 0.25 | 4.5 | 200 | 3.50 |

| Polyimide | 0.20 | 4.0 | 400 | 15.00 |

| CEM-1 | 0.18 | 4.5 | 170 | 2.50 |

| HTG-1 | 0.30 | 3.8 | 350 | 10.00 |

| Aluminium | 205 | 8.4 | 300 | 5.00 |

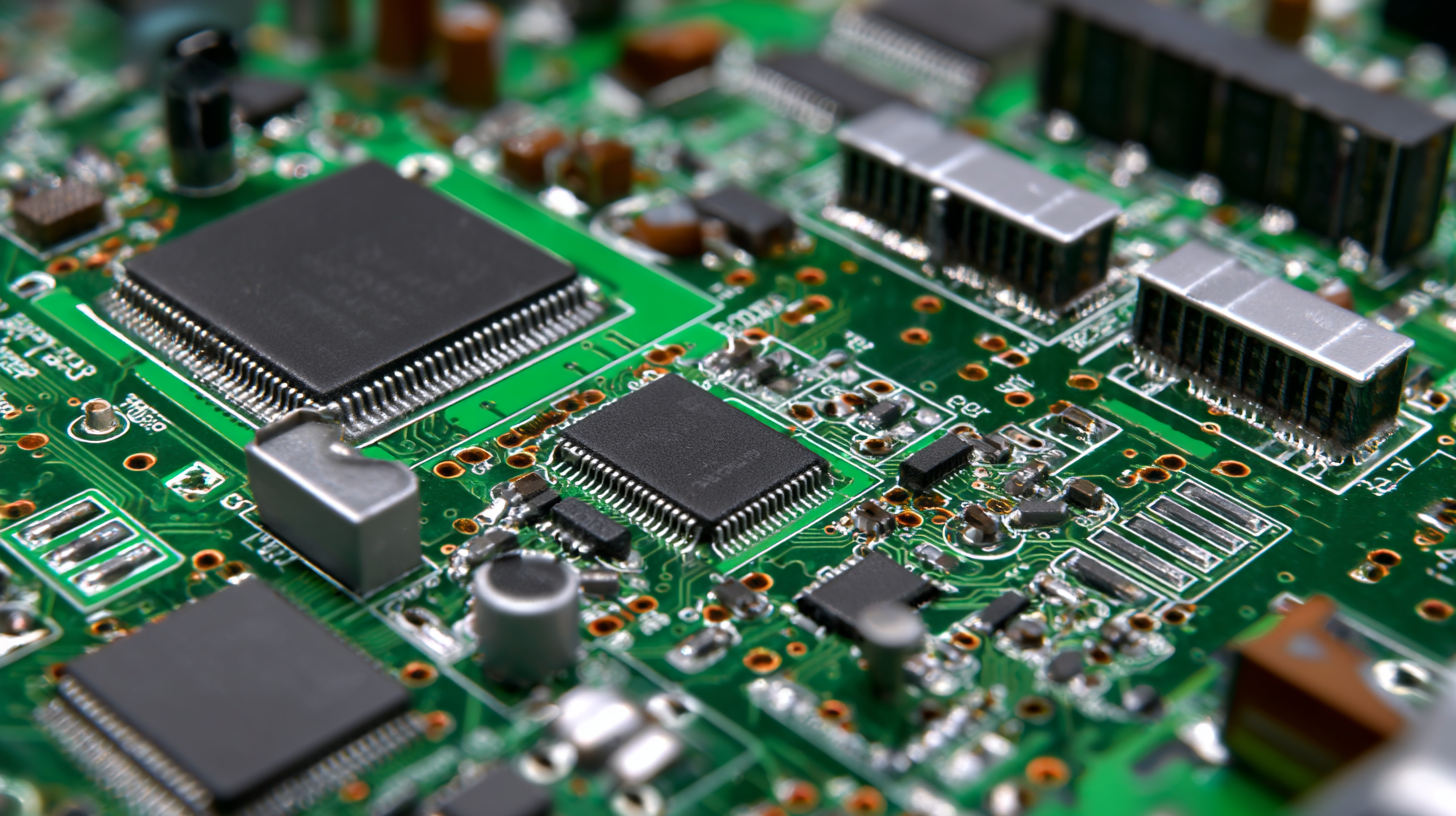

Advanced Manufacturing Techniques: Streamlining Production Processes

The advancement of manufacturing techniques plays a crucial role in shaping the future of printed circuit boards (PCBs). As electronic devices become increasingly complex, the need for streamlined production processes has never been more urgent. Innovations such as additive manufacturing and precision laser cutting are revolutionizing how PCBs are designed and produced. These techniques allow for greater accuracy in component placement, reducing the likelihood of errors and waste in material.

Moreover, automation and robotics have transformed traditional PCB manufacturing, decreasing production time significantly. For instance, automated assembly lines can handle intricate tasks that were once manual, increasing efficiency and throughput. This shift not only enhances the quality of the final product but also provides manufacturers with the flexibility to adapt to rapidly changing market demands. As the electronics industry continues to evolve, these advanced manufacturing techniques will be at the forefront, driving innovation and sustainability in PCB production.

Integration of IoT and Smart Technologies in PCB Design

The integration of IoT and smart technologies in the design of printed circuit boards (PCBs) marks a significant shift in the electronics landscape. As devices become increasingly interconnected, the traditional PCB is evolving to support advanced functionalities. Designers are now focusing on incorporating sensors, wireless communication capabilities, and energy-efficient components directly into PCB layouts. This transformation not only enhances the performance of electronic devices but also streamlines manufacturing processes, allowing for greater compactness and reduced production costs.

Moreover, the rise of smart technologies is driving the demand for PCBs that can facilitate real-time data transmission and processing. The implementation of flexible and multilayer PCBs enables the creation of sleeker and more adaptable products, which is essential for the rapidly changing consumer electronics market. Furthermore, advancements in materials science, such as the use of embedded components and high-frequency laminates, are enhancing signal integrity and overall reliability. As a result, smart devices are becoming more capable, paving the way for innovative applications in sectors like healthcare, automotive, and smart homes.

Sustainability Trends: Eco-Friendly Practices in PCB Development

Sustainability is becoming a critical focus in the development of printed circuit boards (PCBs), especially as the electronics industry grapples with environmental concerns. According to a report by the IPC, an estimated 50 million tons of electronic waste is generated globally every year, shedding light on the urgent need for eco-friendly practices in PCB manufacturing. Innovations such as the use of biodegradable materials and the implementation of circular economy principles are at the forefront of this shift. Manufacturers are increasingly using materials like organic substrates and recyclable metals, which not only reduce landfill waste but also lower the carbon footprint associated with PCB production.

Moreover, recent advancements in manufacturing processes have enabled companies to significantly reduce their resource consumption. The adoption of lead-free solder and the use of environmentally friendly chemicals in PCB fabrication have led to a decrease in harmful emissions. According to the European Electronics Industry's sustainability report, switching to these practices can cut energy consumption by up to 30%. As the industry evolves, embracing sustainability not only serves ecological purposes but also meets the growing consumer demand for environmentally responsible products, indicating a pivotal shift toward greener electronics that is shaping the future of PCBs.

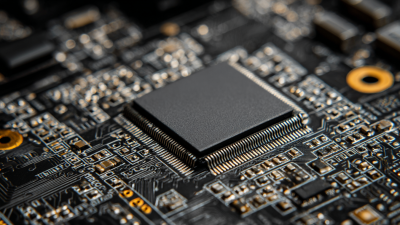

Future-Proofing PCBs: Adapting to Evolving Electronic Demands

As electronic devices continue to evolve, the demand for printed circuit boards (PCBs) is rapidly transforming. Future-proofing PCBs involves not only enhancing their resilience but also ensuring they can integrate seamlessly with emerging technologies. Manufacturers are now focusing on innovative materials and designs that offer better performance, such as flexible substrates and multi-layer configurations. This adaptability allows PCBs to cater to diverse applications, from wearables to smart home devices, thereby addressing the needs of a dynamic market.

Moreover, the future of PCBs lies in their digital integration. Innovations such as advanced prototyping techniques and artificial intelligence-driven design tools are being utilized to streamline the development process, reduce costs, and boost efficiency. By leveraging these technologies, PCB manufacturers can quickly respond to shifting consumer preferences and regulatory changes, ensuring that their products remain competitive. Thus, staying ahead in the PCB market requires a proactive approach, embracing both technological advancements and sustainability practices to align with the evolving landscape of electronics.

Related Posts

-

Transforming Industries: The Future of PCB Production and Its Impact on Technology

-

Unlocking Efficiency: The Future of PCB Production Techniques in Modern Electronics

-

Innovative Trends in PCB Printing That Will Transform the Electronics Industry

-

Understanding the Fundamentals of Circuit Board Design for Beginners

-

Understanding the Importance of Circuit Board Assembly in Modern Electronics

-

The Future of Electronics Innovating with PCB Design Software for Beginners