Transforming Industries: The Future of PCB Production and Its Impact on Technology

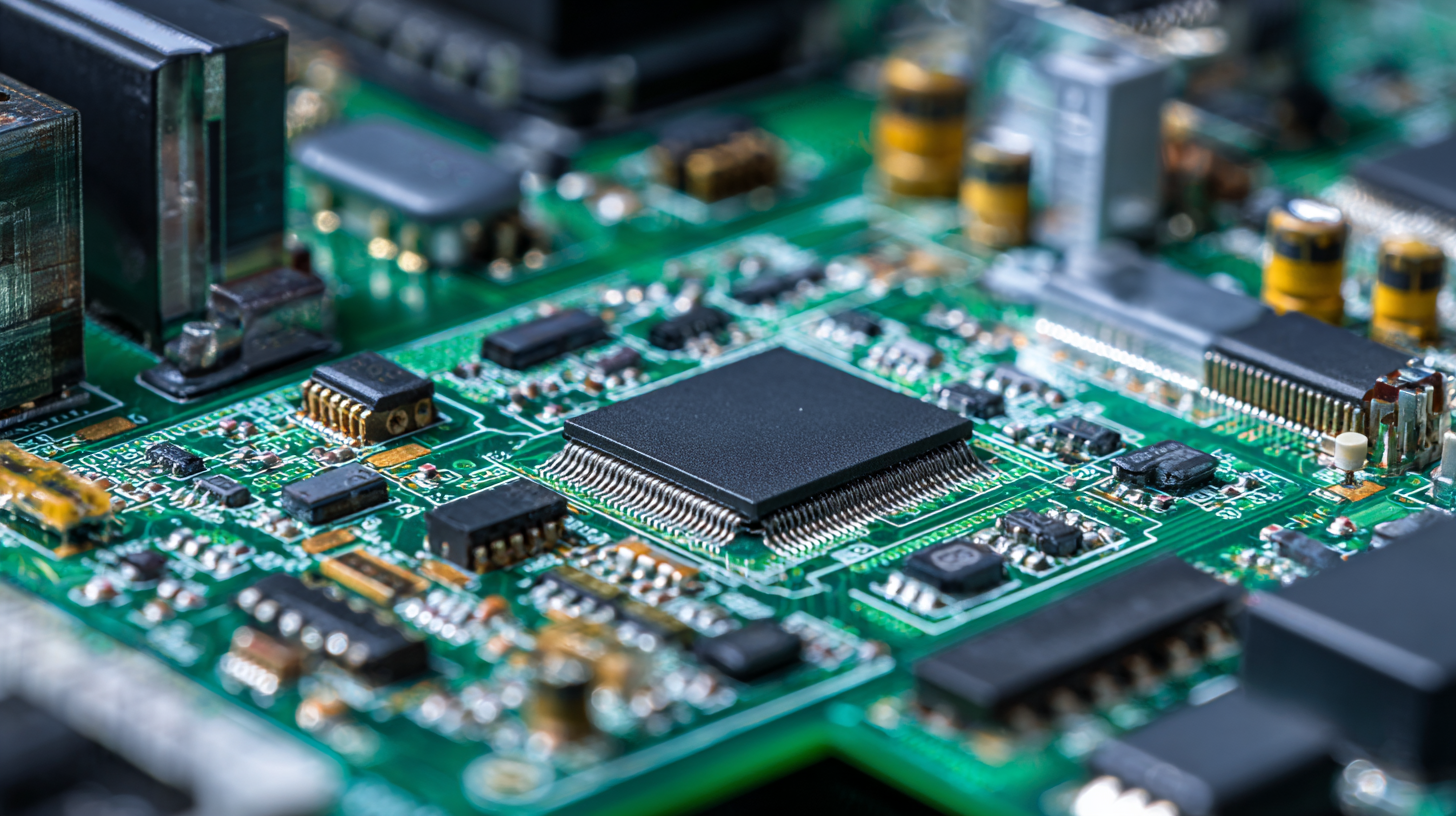

The rapid evolution of technology is fundamentally reshaping the landscape of industries worldwide, with PCB production emerging as a critical focal point. According to a recent report by IPC, the global PCB market is projected to reach $100 billion by 2025, driven by burgeoning demands in sectors such as consumer electronics, automotive, and telecommunications. As industries increasingly adopt automation and IoT technologies, the necessity for advanced printed circuit boards becomes more pronounced, leading to innovations in manufacturing processes. This transformation not only enhances production efficiency and reduces costs but also supports the development of more sophisticated electronics. Therefore, understanding the future of PCB production is essential for stakeholders aiming to leverage technological advancements and stay competitive in an ever-evolving marketplace.

The rapid evolution of technology is fundamentally reshaping the landscape of industries worldwide, with PCB production emerging as a critical focal point. According to a recent report by IPC, the global PCB market is projected to reach $100 billion by 2025, driven by burgeoning demands in sectors such as consumer electronics, automotive, and telecommunications. As industries increasingly adopt automation and IoT technologies, the necessity for advanced printed circuit boards becomes more pronounced, leading to innovations in manufacturing processes. This transformation not only enhances production efficiency and reduces costs but also supports the development of more sophisticated electronics. Therefore, understanding the future of PCB production is essential for stakeholders aiming to leverage technological advancements and stay competitive in an ever-evolving marketplace.

The Evolution of PCB Production Techniques and Their Significance

The evolution of PCB production techniques is significantly reshaping the landscape of technology across various industries. With the emergence of advanced materials such as ultra-low dielectric glass fibers, which boast a lower dielectric constant (Dk), the efficiency of signal transmission in electronic devices is set to improve dramatically. As a crucial component in the semiconductor and circuit board manufacturing domains, these materials not only enhance performance but also cater to the burgeoning demands of sectors such as electric vehicles (EV). The recent patent granted for a novel electroplating process aimed at circuit board production underscores the industry's commitment to innovation, particularly in response to the rapid growth of the EV market.

Meanwhile, companies in the PCB sector are making strategic moves to position themselves favorably in a competitive environment. For instance, a leading service provider in the field has recently submitted an IPO prospectus for a Hong Kong listing, highlighting the growing importance of capital in driving technological advancements. The market for PCB-related products is expected to expand as demand surges, driven by technological integration in industries ranging from consumer electronics to automotive. Data from industry reports indicates that the PCB market in China is projected to experience significant growth, reflecting a shift towards more sophisticated production techniques and materials that can accommodate the demands of emerging technologies.

Exploring Automation and Smart Manufacturing in PCB Industries

The evolution of printed circuit board (PCB) production is increasingly shifting towards automation and smart manufacturing, significantly enhancing operational efficiency and product quality. By integrating advanced technologies such as robotics, artificial intelligence, and Internet of Things (IoT) connectivity, the PCB industry is poised to streamline manufacturing processes. Automated systems allow for greater precision and speed in tasks such as assembly and testing, reducing human error and increasing throughput. This transition not only minimizes production costs but also shortens lead times, enabling manufacturers to respond swiftly to changing market demands.

Moreover, smart manufacturing facilitates real-time monitoring and analytics, empowering companies to optimize their operations continuously. With the ability to collect and analyze data throughout the production lifecycle, manufacturers can identify bottlenecks and inefficiencies, implementing corrective measures instantaneously. This data-driven approach fosters more sustainable practices, as companies can better anticipate resource needs and reduce waste. As the PCB industry embraces these transformative technologies, it lays the groundwork for a more agile, responsive, and innovative future, aligning production capabilities with the rapid advancements in technology across multiple sectors.

Future of PCB Production and Automation Impact

This bar chart illustrates the trend of automation adoption rates and smart manufacturing integration percentages in the PCB industry from 2019 to 2023. The increasing figures indicate a significant shift towards advanced production methods, highlighting the industry's transformation and its impact on technology.

Sustainability in PCB Production: Challenges and Opportunities

The sustainability of PCB production is increasingly becoming a focal point in the electronics industry, driven by the urgent need to address environmental concerns. Traditional PCB manufacturing processes often involve hazardous materials and generate significant waste, prompting a shift towards more eco-friendly practices. Companies are now exploring alternative materials and methods that minimize environmental impact, such as using biodegradable substrates and reducing chemical usage. This transition presents both challenges and opportunities, as manufacturers must invest in research and development to innovate sustainable solutions while maintaining efficiency and cost-effectiveness.

Moreover, the integration of recycling practices into PCB production represents a significant opportunity for improving sustainability. By developing closed-loop systems that allow for the reclamation and repurposing of materials from discarded PCBs, the industry can significantly reduce raw material consumption and waste. Collaborative efforts between manufacturers, suppliers, and regulatory bodies are essential to create effective recycling programs and ensure that sustainable practices are implemented widely. As the demand for environmentally friendly electronics continues to grow, the future of PCB production will likely hinge on balancing innovation with sustainability, ultimately shaping the landscape of technology in a greener direction.

The Role of Advanced Materials in Shaping Future PCBs

The ever-evolving landscape of printed circuit board (PCB) production is increasingly influenced by advanced materials, which play a vital role in enhancing performance and sustainability. As the demand for high-efficiency electronics rises, materials such as low-loss dielectrics, flexible substrates, and high-temperature laminates are being integrated into design and manufacturing practices. According to recent analyses, the global PCB market is projected to reach $80 billion by 2025, underscoring the critical importance of innovation in material science to meet the needs of sectors such as automotive, telecommunications, and consumer electronics.

The automotive industry, in particular, is undergoing a significant transformation, driven by electrification and autonomous technologies. This shift necessitates the development of PCBs that can withstand higher temperatures and offer enhanced thermal management. Research indicates that advanced materials can improve signal integrity and energy efficiency, making them indispensable for the next generation of vehicles. Moreover, initiatives focused on recyclability and carbon recovery from waste PCBs are emerging, aligning production strategies with circular economy principles, thereby further highlighting the role of advanced materials in shaping the future of PCB technology.

Transforming Industries: The Future of PCB Production and Its Impact on Technology - The Role of Advanced Materials in Shaping Future PCBs

| Material Type | Key Properties | Applications | Impact on PCB Performance |

|---|---|---|---|

| FR-4 | Good dielectric properties, flame resistance | Consumer electronics, industrial applications | Standard performance, cost-effective for many applications |

| Polyimide | High thermal stability, flexible | Aerospace, automotive, medical | Enhanced thermal management, suitable for high-performance applications |

| Rogers Materials | Low dielectric constant, high frequency performance | Telecommunications, RF applications | Superior signal integrity and efficiency in high-frequency circuits |

| Ceramic | High thermal conductivity, excellent insulation | Power electronics, RF components | Improved heat dissipation and reliability for demanding applications |

| Thermal Interface Materials (TIMs) | High thermal conductivity, flexible | LEDs, power supplies, high-speed circuitry | Enhances thermal management and performance of PCB assemblies |

Impact of PCB Innovations on Emerging Technologies and Applications

The rapid evolution of printed circuit boards (PCBs) is driving significant innovations across various technology sectors. As industries move toward smarter, more compact solutions, advanced PCB designs now support miniaturization and high-density applications. These innovations enable the development of cutting-edge technologies such as IoT devices, wearable electronics, and electric vehicles, all of which require lightweight and efficient circuit boards to operate effectively.

Tips: When designing PCBs for emerging technologies, consider utilizing multilayer boards to save space while ensuring electrical integrity. Also, employing flexible circuits can enhance the adaptability of your devices, allowing them to fit into unexpected spaces without sacrificing performance.

The impact of PCB innovations extends to energy efficiency and sustainability. With the global push towards greener technologies, manufacturers are now focusing on eco-friendly materials and processes. This shift not only reduces waste but also promotes longer lifespan products that align with environmental goals. As a result, sectors like renewable energy and smart grids benefit greatly from advancements in PCB technology, contributing to a more sustainable future.

Tips: Explore the use of biodegradable materials in PCB production. Additionally, investing in automated manufacturing processes can enhance precision while minimizing errors and resource consumption.