The Best 10 PCB Manufacturing and Assembly Techniques You Should Know?

In the rapidly evolving world of electronics, the significance of PCB manufacturing and assembly cannot be overstated. According to a recent report by ResearchAndMarkets, the global PCB market is expected to reach $80 billion by 2025, driven by rising demand in sectors like automotive and consumer electronics. This highlights the importance of advanced techniques in PCB manufacturing and assembly that can optimize production processes and enhance product quality.

Industry expert Dr. Emily Wang states, "Adopting innovative PCB manufacturing and assembly techniques is crucial for meeting the increasing demands of technology." Her insights elucidate the need for practices such as automated assembly, design for manufacturability, and efficient soldering processes. However, as companies strive for efficiency, challenges like supply chain disruptions and quality control issues often emerge, prompting reevaluation of existing practices.

While the potential for growth in PCB manufacturing and assembly is immense, the pursuit of excellence requires more than just adopting state-of-the-art techniques. Companies must reflect on their operational strategies and address weaknesses that could hinder their competitive edge in the market. Balancing innovation with practical execution is essential for long-term success in this dynamic field.

The Importance of PCB Manufacturing Techniques in Modern Electronics

In today's fast-paced electronic landscape, PCB manufacturing techniques are crucial. Effective processes ensure that devices function correctly. Precision in PCB design can drastically affect the performance of electronic products. Even minor flaws in manufacturing can lead to significant failures later. Engineers need to grasp these techniques to design better and more reliable products.

Quality control is key. A small defect can cause circuit failures, leading to costly recalls. Understanding manufacturing techniques helps in minimizing these risks. Soldering methods, surface treatments, and material choices all impact durability. The trade-offs between cost and quality must be considered carefully.

As technology evolves, so do manufacturing capabilities. New techniques can improve efficiency but may introduce unforeseen challenges. Keeping up with advancements is essential, though overwhelming at times. Designers must remain vigilant and adaptable. They must constantly weigh the benefits against potential pitfalls in PCB production.

The Best 10 PCB Manufacturing and Assembly Techniques You Should Know

| Technique | Description | Advantages | Applications |

|---|---|---|---|

| Surface Mount Technology (SMT) | A method where components are mounted directly onto the surface of PCBs. | High component density, smaller board sizes, and increased reliability. | Consumer electronics, telecommunications. |

| Through-Hole Technology (THT) | Components are inserted into holes and soldered to the PCB. | Robustness and ease of repair. | Power supplies, audio equipment. |

| Mixed-Technology | Combines both SMT and THT on the same board. | Flexibility and optimized performance for diverse applications. | Complex and specialized electronics. |

| Automated Optical Inspection (AOI) | Uses cameras to inspect the assembly process. | Increased quality assurance and defect detection. | Manufacturing processes, quality control. |

| X-ray Inspection | Non-destructive inspection method used for hidden solder joints. | Detects internal defects without damaging the PCB. | High-reliability sectors like aerospace and medical. |

| Reflow Soldering | Melts solder paste on PCB to attach components during heating. | Creates reliable and strong connections. | Most electronic device manufacturing. |

| Wave Soldering | Involves passing a PCB over a wave of molten solder. | Effective for large batches of assemblies. | High-volume production runs. |

| Flex Circuit Technology | Uses flexible substrates for PCB design. | Space-saving and lightweight designs. | Wearable technology, compact devices. |

| PCB Prototyping | Rapid creation of prototype circuits for testing. | Speeds up product development cycles. | R&D, testing new product designs. |

| Hybrid Microelectronics | Combines various electronic components into one package. | High-performance functions in a compact form. | Military, aerospace applications. |

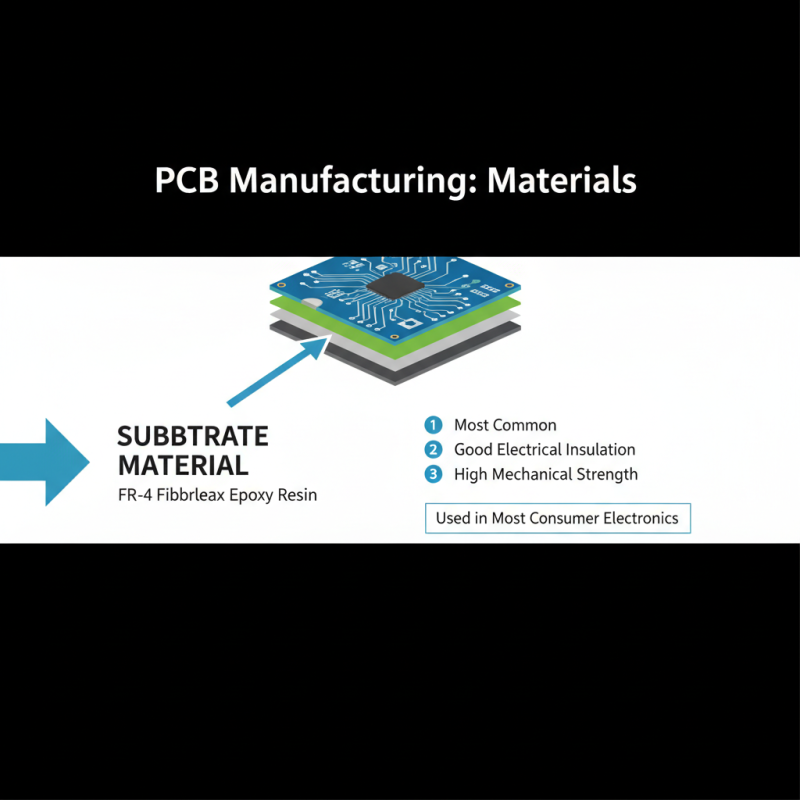

Key Materials Used in PCB Manufacturing: Types and Their Properties

In PCB manufacturing, materials play a crucial role. Different types of materials possess unique properties that affect functionality. The most common substrate is FR-4, a fiberglass epoxy resin. It provides good electrical insulation and mechanical strength. FR-4 is popular for most consumer electronics.

Another important material is copper. It serves as a conductor. The thickness of copper can vary, typically ranging from 1 to 3 ounces. Thicker copper layers enhance current-carrying capacity. However, they can increase costs and complicate the assembly process.

Metal Core PCBs (MCPCBs) are worth noting. They utilize metals like aluminum to dissipate heat effectively. This feature is vital in LED applications. Research indicates that MCPCBs can improve thermal performance by up to 40%. However, they require precise manufacturing techniques. Misalignment during assembly can lead to inefficiencies.

Polyimide is another advanced material. It offers high thermal stability and chemical resistance. It's essential for applications in harsh environments, like aerospace. Yet, it can be more expensive and challenging to process. Balancing material properties with budget constraints remains a common challenge in PCB design.

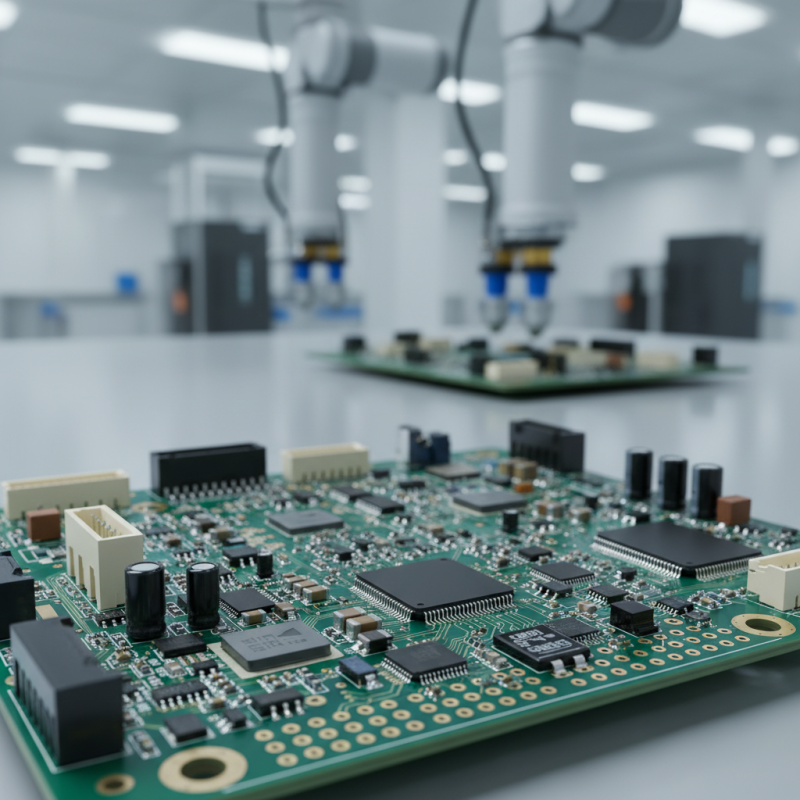

Step-by-Step Process of PCB Assembly: From Design to Production

PCB assembly involves multiple steps, each critical to the final product. It starts with careful design. Designers use software tools to create layouts. They ensure components fit well together. Attention to detail is key here. Even small mistakes at this stage can lead to significant production issues.

Next comes the manufacturing phase. The PCB is printed, etched, and prepared for components. Each process requires precision. A minor error can ruin the entire board. Once manufactured, assembly begins. Components are placed on the board with care. Soldering follows, often using precise machines. Human errors can occur during this phase, affecting quality.

Testing is crucial after assembly. Boards are inspected for defects. Manual and automated tests are both important. Each step must be done correctly. Missing a defect can lead to larger problems later. Reflection on the process can help improve future productions. Overall, the journey from design to production is intricate and demanding.

PCB Manufacturing and Assembly Techniques

This chart illustrates the various techniques used in PCB manufacturing and assembly, showing the percentage of usage in the industry.

Advanced Soldering Techniques: Ensuring Reliable Connections

Advanced soldering techniques are crucial for ensuring reliable connections in PCB manufacturing. Precision is key. Using a fine tip soldering iron can enhance accuracy. The choice of solder is also vital. Lead-free solder is popular but can be challenging to work with. It may require higher temperatures and careful technique.

Temperature control is essential during soldering. Too hot can damage components, while too cool may lead to weak joints. Using a temperature-controlled soldering station can help maintain an optimal range. Practicing various soldering methods can refine your skills. For example, the drag soldering method is effective for arrays of pins, making it easier to create solid connections.

However, challenges remain in any soldering process. Dust and oxidation can impair connections. Cleanliness is often overlooked but essential. Proper cleaning solutions and techniques should be considered. Small errors can lead to significant issues. Inspecting solder joints under magnification can reveal hidden flaws. Embracing both the art and science of soldering allows for continuous improvement in the process.

Quality Control Measures in PCB Manufacturing: Best Practices and Standards

Quality control is vital in PCB manufacturing. Ensuring the reliability of printed circuit boards requires strict measures. Regular inspections can catch potential issues early. However, many manufacturers still overlook basic checks. This can lead to problems down the line, impacting performance.

Implementing standards like IPC-600 and IPC-A-610 is essential. These guidelines help in evaluating PCB quality. Visual inspections and functional testing should be a routine part of this process. Yet, the human factor can introduce errors. Training staff is crucial, but often neglected. A lack of awareness can lead to faulty assembly.

Traceability is another concern. Keeping records of materials and processes helps identify problems. Many companies fail to document this information effectively. As a result, issues might resurface without clear understanding. Combining technology with proper training can mitigate risks. This blend is necessary for maintaining consistent quality in PCB manufacturing.

Related Posts

-

How to Choose the Best PCB Maker for Your Electronics Projects

-

Top 10 Printed Circuit Board Manufacturers You Should Know About

-

Innovative Trends in PCB Printing That Will Transform the Electronics Industry

-

Top 5 Essential Features of High Quality PCB Boards for Your Projects

-

Top 5 US Based PCB Manufacturers to Watch in 2025

-

2025 Top 5 Trends in Circuit Board Design You Can't Afford to Miss